Inner Grooved Low Finned Tubes For Heat Exchanger

Inner Grooved Low Finned Tubes

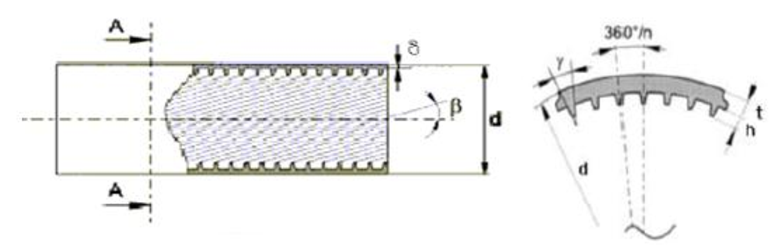

Inner Grooved Low Finned Tubesalso known as steam finned tubes, inner finned tubes, low Inner Grooved Low Finned Tubesare ordinary heat exchange tubes that are rolled to form threads on their inner surface, and the fins are removed from the bare tube by rolling rolls The outer wall rolls out. A high-efficiency heat exchange tube type with tubes and fins in the same tube.

Inner Grooved Low Finned Tubes are usually made of copper and are always made with vertical rods for easier installation.

The strengthening effect of this Inner Grooved Low Finned Tubes is outside the tube. The strengthening effect on the medium is reflected in the fact that the threaded fins increase the heat exchange area on the one hand; on the other hand, when the shell-side medium flows through the surface of the threaded pipe, the surface threaded fins have a dividing effect on the laminar flow edge layer and thin the boundary. layer thickness. Moreover, the turbulence formed on the surface is also stronger than that of the light pipe, which further reduces the thickness of the boundary layer. As a result of the combined effect, the tube type has a high heat transfer capacity. When this tube type is used for evaporation, it can increase the number of bubbles formed on the unit surface and improve the boiling heat transfer capacity; when it is used for condensation, the threaded fins are very conducive to the dripping of the condensate at the lower end of the tube, reducing the liquid film. Thin, thermal resistance is reduced, and condensation heat transfer efficiency is improved.

Inner Grooved Low Finned Tubes Quick Details:

Standard: ys/t440, gb/t 19447 or equivalent ASTM B359 ASME SB359;

Material: red Cooper T2/TP2, Cooper magnesium iron alloy BFe 10-1-1, miscellaneous brass Hsn 701, HA177-2, etc.

Outer diameter (OD): 7-16mm

Tube length: up to 16000mm

Fin height: 1.2mm ~2.77mm

Fin thickness: about 0.3mm

Rotation angle: 0-28°

Fin pitch: 30 FPI/28 FPI/26 FPI/36 FPI/43 FPI

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

Data sheet of Inner Grooved Low Finned Tubes

| Plain tube (mm) | Finned section dimensions (mm) | Ratio | De | |||

| D×t | Tp | dd | dr | di | η | mm |

| 19×2 | 0.8 | 18.8 | 17 | 134 | 2.8 | 17.9 |

| 19×2 | 1 | 18.8 | 16.8 | 13.4 | 2.5 | 17.8 |

| 19×2 | 1.25 | 18.8 | 16.6 | 13 | 2.2 | 17.8 |

| 19×2 | 1.5 | 18.8 | 16.6 | 13 | 2 | 17.7 |

| 19×2 | 2 | 18.8 | 16.4 | 13 | 1.7 | 17.5 |

| 25×2.5 | 0.8 | 24.8 | 23 | 18.8 | 2.8 | 23.9 |

| 25×2.5 | 1 | 24.8 | 22.6 | 18.8 | 2.75 | 23.7 |

| 25×2.5 | 1.25 | 24.8 | 22.3 | 18 | 2.5 | 23.6 |

| 25×2.5 | 1.5 | 24.8 | 22.3 | 18 | 2.2 | 23.5 |

| 25×2.5 | 2 | 24.8 | 22 | 18 | 1.8 | 23.4 |

| 25×2.5 | 2.5 | 24.8 | 22 | 18 | 1.6 | 23.3 |

|

D------Outside diameter of plain end section Dof----Diameter of top fins Dr-----Root diameter of finned section Di-----Inside diameter of finned section T------Wall thickness of plain end section Tp-----Fin pitch De----Equivalent diameter of finned tube L------Plain tube end length |

||||||

| Please email us for more information. | ||||||

We can provide monolithic low finned tubes with no fin section clearance (min. 5mm) in the middle of the core tube, or bent to the designed bend radius.

Example:

Manufacturing Process:

Inner Grooved Low Finned Tubes are ordinary heat exchange tubes that are rolled to form threads on the inner surface, and the fins are rolled out from the outer wall of the plain tube through rollers. A high-efficiency heat exchange tube type with tubes and fins in the same tube.

Delivery conditions:

The tube ends are square cut, free of burrs, dry and blown clean on the inside and varnished on the outside.

Put desiccant in each package for continental shipping.

Quality Test:

The integral low fin tube quality is assured by hydrostatic or pneumatic tests, eddy current tests & MARCO tests in order to verify design specifications.

Acceptance ceritia:

WOLVERINE / HPT / GEWA-K & GEWA-KS

Features of Inner Grooved Low Finned Tubes

⑴ low processing cost;

⑵ wide application. It has a strengthening effect on the evaporation, condensation, gaseous heat transfer and liquid heat transfer of the shell-side medium;

3. The inner surface area is 1.5-2 times that of ordinary pipes, and the thermal conductivity is 1.5-2.4 times that of ordinary pipes of the same size. The flow resistance is only increased by 3%-5%, saving 20%-35% of energy, reducing

Air conditioner weight 10%-25%.

Packaging: Iron frame packing box

Application

Inner Grooved Low Finned Tubes are mainly used in petrochemical, power, paper, tobacco, building heating and other industries, such as air coolers, air heaters, food industry vegetable protein powder, starch and other air heater spray drying systems.

As long as the medium on the shell side is relatively clean, free from corrosion and scaling, low-thread finned tubes can be used as heat exchange elements to form a low-thread finned-tube type high-efficiency heat exchanger.

The working temperature is up to 250 degrees.

![field:title/]](/uploads/220318/1-22031QH92b21.png)

![field:title/]](/uploads/220318/1-22031QI359256.jpg)

![field:title/]](/uploads/220318/1-22031QG3434U.png)

![field:title/]](/uploads/220318/1-22031QA14I91.png)

![field:title/]](/uploads/220318/1-22031Q62510194.png)

![field:title/]](/uploads/220318/1-22031Q60ZJE.jpg)

![field:title/]](/uploads/220317/1-22031G620064D.jpg)

![field:title/]](/uploads/220317/1-22031G60KT56.png)