All staff cleaning

Beite Steel Pipe full participation, full cleaning, and self-inspection and sorting activities in each area.

In order to actively implement the company's lean thinking and strive to create a clean and tidy working environment, on the morning of May 25, Beite Steel Pipe issued a call for "full participation and full cleaning", and various regions carried out 5S self-inspection and sorting activities.

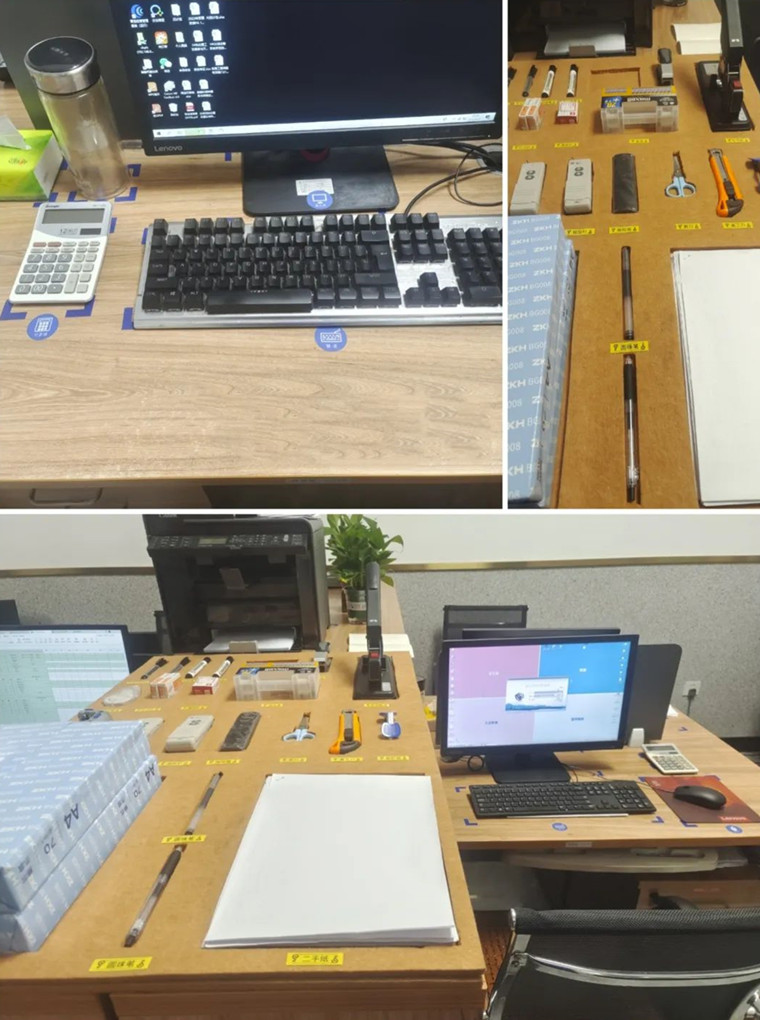

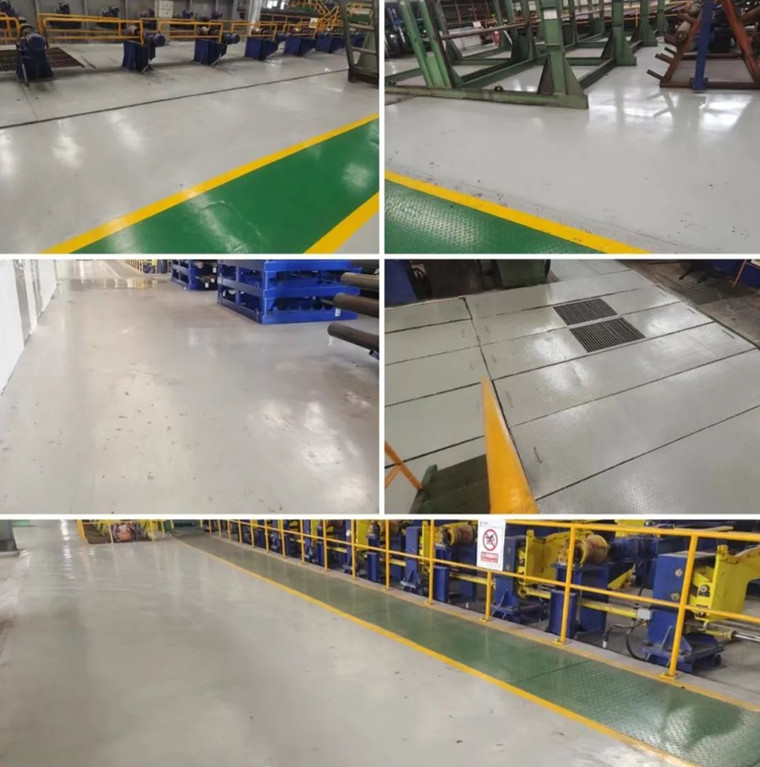

On the day of the event, all production sites and offices responded to the call and devoted themselves to the cleaning work, sorting out unnecessary items, positioning office supplies, and cleaning dirty, messy, and cluttered areas. After an hour of cleaning, the factory looks brand new.

Lean management has always been one of the main starting points for the high-quality development of Beite Steel Pipe. A good on-site working environment is not only a guarantee for the physical and mental health of employees, but also an important part of the company's brand building. Improvement starts from small things. Only by constantly doing detailed work and forming standardization can a good atmosphere for improvement be created.

![field:title/]](/uploads/230608/1-23060QH042V2.jpg)

![field:title/]](/uploads/230529/1-230529162429631.jpg)

![field:title/]](/uploads/230515/1-2305151K92O02.jpg)

![field:title/]](/uploads/230411/1-2304111G941616.jpg)

![field:title/]](/uploads/230324/1-230324163KQQ.jpg)

![field:title/]](/uploads/230206/1-230206195510331.jpg)

![field:title/]](/uploads/221205/1-2212051A606401.jpg)

![field:title/]](/uploads/221108/1-22110Q11111543.png)