Four welding methods for stainless steel pipes

Four welding methods for stainless steel pipes

The welding of stainless steel pipes usually consists of bottom welding, filling welding and cover welding.

Bottom welding is the most critical part of stainless steel pipe welding. It is not only related to the quality of the project, but also to the progress of the project. At present, stainless steel bottoming is divided into two processes: backside argon and non-argon. The back argon protection is divided into solid core wire + TIG process and solid core wire + TIG + water-soluble paper process; the back side is not filled with argon protection is divided into flux cored wire bottom welding and welding rod (coated wire) bottoming TIG welding.

The welding of stainless steel pipe usually consists of bottom welding, filling welding, and cover welding. Stainless steel pipe bottom welding is the most critical part of stainless steel pipe welding. It is not only related to the quality of the project, but also to the progress of the project. At present, stainless steel bottoming is divided into two processes: backside argon and non-argon. The back argon protection is divided into solid core wire + TIG process and solid core wire + TIG + water-soluble paper process; the back side is not filled with argon protection is divided into flux cored wire bottom welding and welding rod (coated wire) bottoming TIG welding.

Several methods used in stainless steel bottom welding

Stainless steel backing welding usually adopts TIG process. According to the actual situation on site, we can use the following four methods for backing welding.

①The method of blocking ventilation protection by using a blocking plate on the back;

②Use only soluble paper or a combination of soluble paper and blocking plate for plugging and ventilating protection;

③Using flux-cored wire for bottom TIG welding.

④TIG welding is used for bottom TIG welding with coated welding wire (self-shielded welding wire).

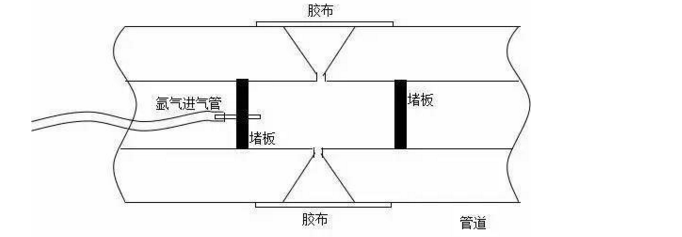

1. The back side uses a blocking plate to block the ventilation protection method (ie solid core welding wire + TIG)

When stainless steel pipes are prefabricated, the welding joints can usually be welded by rotation, and ventilation is very easy. At this time, the method of blocking and ventilating both sides of the pipe inner welding joints is usually used to perform the bottom welding (see Figure 1), and the outside Seal with adhesive cloth.

When welding, the process of ventilating in advance and lagging the air should be adopted. The outer adhesive cloth is torn off by welding. Since the blocking plate is composed of rubber and white iron, it is not easy to damage, so this welding method can guarantee the inside of the weld. It is filled with argon gas and its purity is ensured, so as to effectively ensure that the metal inside the weld is not oxidized, and the quality of the bottom weld of the weld is guaranteed.

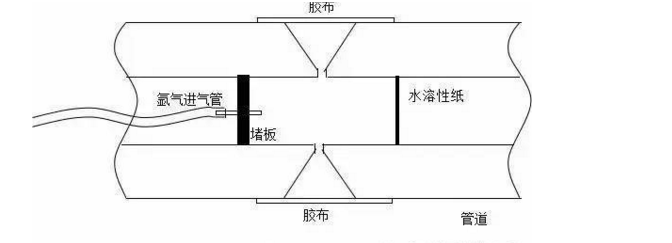

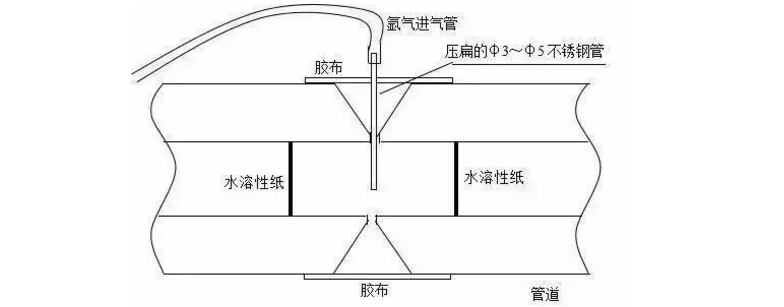

2. Use only soluble paper or a combination of soluble paper and blocking plate for blocking ventilation protection (ie solid welding wire + TIG + water-soluble paper)

When installing and welding stainless steel pipe fixing ports, it is difficult to ventilate inside, and some sides are easier to plug. In this case, water-soluble paper + blocking plate can be used for plugging. That is, the side that is easy to ventilate and easy to remove is blocked with a blocking plate, and the side that is not easy to ventilate and difficult to remove the blocking plate is blocked with water-soluble paper, and the outside is sealed with adhesive cloth to paste the weld seam (see Figure 2 ).

When using water-soluble paper to seal the ventilation, because the ventilation is from the center of the weld, in the final sealing step, the ventilation tube should be quickly pulled out, and the remaining argon gas inside should be used for protection, and the bottom can be quickly completed and the mouth sealed.

With this method, it should be noted that the water-soluble paper should be double-layered and must be pasted, otherwise it will easily cause the water-soluble paper to be damaged and fall off, and the inner weld will lose the protection of argon gas, which will cause oxidation, which will cause the weld to be cut again. Welding can not guarantee the quality of welding, but also seriously affects the construction period. Therefore, we should strictly inspect before welding and stick water-soluble paper.

In many construction sites, we have adopted this welding method for bottoming. The quality can be effectively guaranteed. At the same time, there are certain construction difficulties. Therefore, careful and skilled welders should be selected for this work.

3. The back side is not protected by argon gas, and the flux cored wire + TIG process is adopted

This method has been applied in my country for several years, and flux-cored welding wires such as E308T1-1, E308LT1-1, E309T1-1, E309LT1-1, 347T1-1, E316T1-1, E316LT1-1 have been produced, and they have been applied to the field. The welding has achieved good economic benefits.

Since the back is not filled with argon, its advantages are obvious, mainly in terms of high efficiency, simplicity, and low cost, which are suitable for installation on the construction site. However, due to its structural characteristics, the flux-cored welding wire has higher requirements on the welder during operation. Its wire feeding speed is fast, and the wire feeding accuracy is required to be high. It is difficult to master. Welders should be specially trained and skilled in welding before they can participate in welding. In Nanjing Yangba and overseas construction sites, we applied this method to successfully solve the problem that argon gas cannot be passed through the contact port and the repair port.

4. The back side is not protected by argon gas, and the coated welding wire (self-protected flux cored wire) + TIG process is adopted

In the 1990s, Japan's Kobelco and other companies developed base welding wires. In recent years, my country has also developed stainless steel base welding wires (namely, coated welding wires, such as TGF308, TGF308L, TGF309, TGF316L, TGF347, etc.) , And used in actual construction, and achieved good results. We successfully used this method in Urumqi Petrochemical's capacity expansion and transformation project.

The protection mechanism of the stainless steel bottoming wire + TIG process is that the back weld is protected by the metallurgical reaction of the slag produced by the melting of the wire and its alloy elements, and the front weld is protected by argon, slag and alloy elements.

With this process, the following operating points should be noted: During the welding process, maintain the correct included angle between the welding torch, welding wire, and welding parts. The ideal backward inclination angle of the welding torch nozzle is 70°-80°, and the welding wire is clamped to the surface of the weldment. The angle is 15°-20°; the temperature of the molten pool is correctly controlled, and the temperature of the molten pool is changed by changing the angle between the welding handle and the weldment, changing the welding speed, etc., so as to ensure the beautiful shape of the weld (the width is consistent, no recession, Defects such as over-convex);

During operation, the current should be slightly larger than when welding solid wire, and the welding handle should be slightly oscillated to accelerate the separation of molten iron and molten coating, which is convenient for observing the molten pool and controlling whether the weld is penetrated; when filling the wire, it is best to send it to Half of the molten pool, and press it inward slightly to ensure the penetration of the root and prevent recession;

During the welding process, the welding wire should be fed in and taken out regularly, and the welding wire should always be under the protection of argon gas to prevent the end of the welding wire from being oxidized and affecting the welding quality; pay attention to the welding quality at the arc starting and ending points, and the arc starting point The spot weld should be polished to a 45° gentle slope, and attention should be paid to defects such as arc craters and shrinkage holes when closing the arc.

The welding wire is used for bottom welding, and there is no need to pass argon gas inside the weld. The welder is simple and quick to operate, has the characteristics of high efficiency and low cost, and can also guarantee the welding quality. (In the Urumqi Petrochemical Expansion Project, we We use this method to weld a total of 28 joints and repair ports, and the pass rate of one-time perspective welding is 100%), which is worthy of our promotion and use.

The above four stainless steel bottom welding methods have their own advantages and disadvantages. In actual construction, we should consider not only the construction cost, but also the welding quality and construction schedule, according to the specific conditions of the site, and rationally select the construction process.

![field:title/]](/uploads/220425/1-22042511053I30.jpg)

![field:title/]](/uploads/220414/1-220414214051492.jpg)

![field:title/]](/uploads/211104/1-211104121004V0.jpg)

![field:title/]](/uploads/211102/1-21110215254UP.jpg)

![field:title/]](/uploads/210923/1-2109231045325B.png)

![field:title/]](/uploads/200915/1-2009151K634949.jpg)

![field:title/]](/uploads/210813/1-210Q31QA0b0.jpg)

![field:title/]](/uploads/210629/1-2106291U944F9.jpg)