ASTM A210 ASME SA210 Grade C Seamless Tubes

ASTM A210 Grade C Seamless Medium-Carbon Steel Boiler and Superheater Tubes

Standard:ASTM A210/A210M

ASTM A210 Grade C Seamless Boiler and Superheater Tubes sizes and thicknesses usually furnished to this specification are 1/2 in. to 5 in. [12.7 to 127 mm] in outside diameter and 0.035 to in. 0.500 [0.9 to 12.7 mm], inclusive, in minimum wall thickness.

ASTM A210 ASME SA210 Grade C Seamless Medium-Carbon Steel Boiler and Superheater Tubes

SA-210C is ASME standard steel grade, which is medium carbon steel pipe for boiler and superheater pipe, pearlescent hot strong steel;

Applicable conditions: widely used in 300MW, 600MW and other large capacity power station boilers, heating surface piping and header, steam water piping, etc. with working temperature lower than 500 ℃, such as water wall, economizer, low-temperature superheater, etc.

ASTM A210 Grade C Seamless Boiler and Superheater Tubes Quick Details

Manufacture:Seamless process ,Hot-finished or Cold-finished

Wall thickness(WT): 0.9 mm——12.7 mm.

Outer diameter (OD): 12.7 mm——127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished (Outside only) to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

ASTM A210 Grade C Seamless Boiler and Superheater Tubes

| OD (mm) | Wall Thickness(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

Manufacture

ASTM A210 Grade C Seamless boiler tubes are made by the seamless process and are either hot-finished or cold-finished, as specified.

Heat Treatment

Hot-finished tubes need not be heat treated.

Cold- finished tubes shall be given a subcritical anneal, a full anneal, or a normalizing heat treatment after the final cold finishing process.

Chemical Composition Of ASTM A210 Grade C

| ASTM A210 | Grade | chemical composition: | ||||

| C(a) | Si | Mn | P | S | ||

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | |

Mechanical Properties Of ASTM A210 Grade C

| Mechanical Properties | Grade C |

| Tensile strength, min, ksi [MPa] | 70 [485] |

| Yield strength, min, ksi [MPa] | 40 [275] |

| Elongation % | 30 |

| HRB | 89 |

| HB | 179 |

The dimensional tolerances of ASTM A210 Seamless Medium-Carbon Steel Boiler and Superheater Tubes

s

Tolerances of Wall Thickness

|

Outside Diameter, in. [mm] |

Wall Thickness, % | |||||||

| 0.095[2.4] and Under |

Over 0.095 to 0.150 [2.4 to 3.8], incl |

Over 0.150 to 0.180 [3.8 to 4.6], incl |

Over 0.180,[4.6] | |||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Hot-Finished Tubes | ||||||||

| 4 [101.6] and under | 40 | 0 | 35 | 0 | 33 | 0 | 28 | 0 |

| Over4[101.6] | .... | .... | 35 | 0 | 33 | 0 | 28 | 0 |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Outside Diameter,in. [mm] | Permissible Variations, in. [mm] | |

| Over | Under | |

| Hot-Finished Seamless Tubes | ||

| 4 [101.6] and under | 1 ⁄ 64 [0.4] | 1 ⁄ 32 [0.8] |

| Over 4 to 7 1 ⁄ 2 [101.6 to 190.5], incl | 1 ⁄ 64 [0.4] | 3 ⁄ 64 [1.2] |

| Over 7 1 ⁄ 2 to 9 [190.5 to 228.6], incl | 1 ⁄ 64 [0.4] | 1 ⁄ 16 [1.6] |

| Cold-Finished Seamless Tubes | ||

| Under 1 [25.4] | 0.004 [0.1] | 0.004 [0.1] |

| 1 to 1 1 ⁄ 2 [25.4 to 38.1], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [38.1 to 50.8], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50.8 to 63.5], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [63.5 to 76.2], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [76.2 to 101.6], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [101.6 to 190.5], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [190.5 to 228.6], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

|

Method of Manufacture |

Outside Diameter, in. [mm] |

Cut Length,in. [mm] | |

| Over | Under | ||

| Seamless, hot-finished | All sizes | 3 ⁄ 16 [5] | 0 [0] |

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] and over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] and over | 3 ⁄ 16 [5] | 0 [0] | |

Mechanical Tests Required

(1)Tension Test—One tension test shall be made on a specimen for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes .

(2)Flattening Test—One flattening test shall be made on specimens from each end of one finished tube from each lot.

(3)Flaring Test—One flaring test shall be made on speci- mens from each end of the one finished tube from each lot.

(4)Hardness Test—Brinell or Rockwell hardness tests shall be made on specimens from two tubes from each lot .

(5)Hydrostatic or Nondestructive Electric Test—Each tube shall be subjected to the hydrostatic,

ASTM A210 Grade C Seamless Boiler Tubes Marking

In addition to the marking prescribed in Specification A 450/A 450M, the marking shall indicate whether the tube is hot-finished or cold-finished.

Surface Condition

If pickling or shot blasting or both are required, this shall be specifically stated in the order.

Ordering Information

Orders for material includes the following, as required, to describe the desired material adequately:

(1)Quantity (feet, metres, or number of lengths),

(2) Name of material (seamless tubes),

(3) Grade C,

(4) Manufacture (hot-finished or cold-finished),

(5) Size (outside diameter and minimum wall thickness),

(6) Length (specific or random),

(7) Test report required, (see Certification Section of Specification A 450/A 450M),

(8) Special requirements.

Note: Material furnished under ASTM A210 conform to the applicable requirements of the current edition of Specification A 450/A 450M

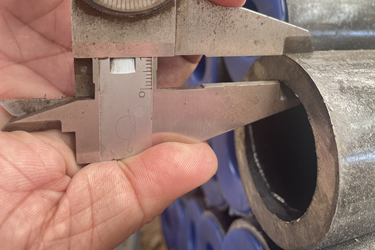

Photos of ASTM A210 Grade C Alloy-Steel Boiler and Superheater Tubes

Application of SA-210C boiler pipe in utility boiler:

SA-210C boiler pipe is widely used in large-scale thermal power generation boilers. The thermal power units using SA-210C steel pipe mainly include: 300000 kW subcritical unit; 300000 kW CFB boiler; 600000 kW supercritical unit; 600000 kW subcritical unit.

Selection of SA-210C welding material

SA-210C has good welding performance. Generally, there is no preheating before welding and no heat treatment after welding. Two kinds of butt welding processes are involved in the actual production. They are the same kind of steel butt joints: GTAW butt joint (H08Mn2SiA welding wire), GTAW backing + SMAW cover butt joint (h05mnsialtizra welding wire + CH welding wire) E507 electrode), welding slope (one side) is 35 ± 1%.

Sa.210c bending process

SA-210C belongs to medium carbon Meng steel high pressure boiler pipe, which has good cold and hot working performance, but should avoid the blue brittle temperature elbow of about 250 ° C. During cold bending, heat treatment is required when the ratio of bending radius to outer diameter of steel pipe is less than 2.5: when the temperature of hot bending is 870-980 ℃, heat treatment is required when the ratio of bending radius to outer diameter of steel pipe is less than 1.25.

Please fill the following form.

![field:title/]](/uploads/191012/1-1910120U51N14.jpg)