ASTM B338 Grade 17 Titanium Seamless Pipe

ASTM B338 Grade 17 Titanium Seamless Pipe

ASTM B338 Grade 17—UNS R52252. Unalloyed titanium plus 0.04 to 0.08 % palladium Seamless Pipe

Standard:

ASTM B861 Standard Specification for Titanium and Titanium Alloy Seamless Pipe

ASTM B338 Grade 17—UNS R52252. Unalloyed titanium plus 0.04 to 0.08 % palladium Seamless Pipeintended for surface condensers, evaporators, and heat exchangers

ASTM B338 Grade 17 Titanium Seamless Pipe Quick Details

Manufacture:Seamless process ,Cold-drawn

Wall thickness(WT): 0.5 mm-12.7 mm.

Outer diameter (OD): 12.7 mm-219 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms: T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

Materials and Manufacture

Seamless tube shall be made from hollow billet by any cold reducing or cold drawing process that will yield a product meeting the requirements ofthis specification. Seamless tube is produced with a continuous periphery in all stages of manufacturing operations.

Chemical Composition of ASTM B338 Grade 17 Titanium Seamless Pipe

| Chemical Composition(%) | ||||||||

| C,max | O,max | N,max | H,max | Fe,max | Pd,max |

Other Elements, max. each |

Other Elements, max. total |

Ti |

| 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | 0.04-0.08 | 0.1 | 0.4 | Balance |

Product Analysis

Product analysis tolerances, listed in Table 2, do not broaden the specified heat analysis requirements, but cover variations between different laboratories in the measurement of chemical content.

| Element% | ||

| Maximum or Specified Range | Permissible Variation in Product Analysis | |

| Aluminum | 0.5 to 2.5 | ±0.20 |

| Aluminum | 2.5 to 3.5 | ±0.40 |

| Carbon | 0.10 | +0.02 |

| Chromium | 0.1 to 0.2 | ±0.02 |

| Cobalt | 0.2 to 0.8 | ±0.05 |

| Hydrogen | 0.015 | +0.002 |

| Iron | 0.80 | +0.15 |

| Iron | 1.2 to 1.8 | ±0.20 |

| Molybdenum | 0.2 to 0.4 | ±0.03 |

| Molybdenum | 1.5 to 4.5 | ±0.20 |

| Nickel | 0.3 to 0.9 | ±0.05 |

| Niobium | >30 | ±0.50 |

| Nitrogen | 0.05 | +0.02 |

| Oxygen | 0.30 | +0.03 |

| Oxygen | 0.31 to 0.40 | ±0.04 |

| Palladium | 0.01 to 0.02 | ±0.002 |

| Palladium | 0.04 to 0.25 | ±0.02 |

| Ruthenium | 0.02 to 0.04 | ±0.005 |

| Ruthenium | 0.04 to 0.06 | ±0.005 |

| Ruthenium | 0.08 to 0.14 | ±0.01 |

| Silicon | 0.06 to 0.50 | ±0.02 |

| Vanadium | 2.0 to 3.0 | ±0.15 |

| Residuals A (each) | 0.1 | +0.02 |

Tensile Requirements of ASTM B338 Grade 17 Titanium Seamless Pipe

The room temperature tensile properties of the tube in the condition normally supplied shall conform to the requirements prescribed in Table 3.

| Grade | Tensile Strength, min | Yield Strength (0.2 % Offset) | Elongation 2 in. Or 50 mm | ||||

| ksi | (MPa) | min. | max. | gage length,min % | |||

| ksi | (MPa) | ksi | (MPa) | ||||

| 1 | 35 | (240) | 20 | (138) | 45 | (310) | 24 |

Testings

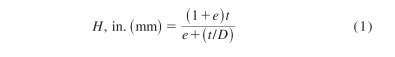

Flattening Test

Tubing shall withstand, without cracking, flattening under a load applied gradually at room temperature until the distance between the load platens is not more than H in. H is calculated as follows:

H = the minimum flattened height, in. (mm),

t = the nominal wall thickness, in. (mm) and,

D = the nominal tube diameter, in. (mm).

For Grades 17:

e =0.07 in. for all diameters

Flaring Test

For tube 3 1 ⁄ 2 in. (88 mm) in outside diameter and smaller, and 0.134 in. (3.4 mm) in wall thickness and thinner,a section of tube approximately 4 in. (102 mm) in length shall withstand being flared with a tool having a 60° included angle until the tube at the mouth of the flare has been expanded in accordance with Table 5.The flared end shall show no cracking or rupture visible to the unaided eye.

| Grade | Expansion of Inside Diameter,min, % |

| 17 | 22 |

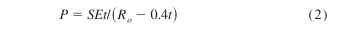

Hydrostatic Test

Each length of pipe shall withstand, without showing bulges, leaks, or other defects, an internal hydrostatic pressure that will produce in the pipe wall a stress of 50 % of the minimum specified yield strength at room temperature. This pressure shall be determined by the equation:

P = minimum hydrostatic test pressure, psi (or MPa),

S = allowable fiber stress of one-half the minimum yield strength, psi (or MPa),

t = wall thickness, in. (or mm),

R o = outside tube radius, in. (or mm), and

E = 1.0 seamless pipe.

The maximum hydrostatic test pressure shall not exceed 2500 psi (17.2 MPa) for sizes 3 in. (76 mm) and under, or 2800 psi (19.3 MPa) for sizes over 3 in. Hydrostatic pressure shall be maintained for not less than 5 s.

Permissible Variation in Dimensions

Variations in dimensions from those specified shall not exceed the amounts prescribed in Table 5.

Straightness—The maximum uniform bow shall not exceed the values given in Table 6.

Squareness of Cut—The angle of cut of the end of any tube may depart from square by not more than 0.016 in./in. of diameter.

| Outside Diameter, in. (mm) |

Diameter Tolerance, in. (mm) A,B,C |

Permissible Variations D in Wall Thickness, t, % |

| Under 1 (25.4), excl | ±0.004 (±0.102) | ±10 |

| 1 to 1 1 ⁄ 2 (25.4 to 38.1), excl | ±0.005 (±0.127) | ±10 |

| 1 1 ⁄ 2 to 2 (38.1 to 50.8), exc | ±0.006 (±0.152) | ±10 |

| 2 to 2 1 ⁄ 2 (50.8 to 63.5), excl | ±0.007 (±0.178) | ±10 |

| 2 1 ⁄ 2 to 3 1 ⁄ 2 (63.5 to 88.9), excl | ±0.010 (±0.254) | ±10 |

| Length, ft (m) | Maximum Curvature Depth of Arc |

| Over 3 to 6 (0.91 to 1.83), incl | 1 ⁄ 8 in. (3.2 mm) |

| Over 6 to 8 (1.83 to 2.44), incl | 3 ⁄ 1 6 in. (4.8 mm) |

| Over 8 to 10 (2.44 to 3.05), incl | 1 ⁄ 4 in. (6.4 mm) |

| Over 10 (3.05) | 1 ⁄ 4 in./any 10 ft (2.1 mm/m) |

Finish

The finished tube shall be clean and free of foreign material, shall have smooth ends free ofburrs, and shall be free of injurious external and internal imperfections.

Packaging and Package Marking

The tube will be packaged in accordance with the manufacturer’s standard practice, unless otherwise agreed upon between the manufacturer and the purchaser and so stated in the purchase order.

Certification

Note:

All tubes shall be supplied as per applicable ASTM B338 /B338M Specification

Mill test certificates will be issued

We can provide 3.2 Certification according to the needs of you

![field:title/]](/uploads/221213/1-221213205I5212.jpg)

![field:title/]](/uploads/221213/1-22121320502J02.png)

![field:title/]](/uploads/221213/1-221213203416295.png)

![field:title/]](/uploads/221213/1-221213202626359.png)

![field:title/]](/uploads/221213/1-22121319523N60.jpg)

![field:title/]](/uploads/221212/1-22121216243Q24.jpg)

![field:title/]](/uploads/221213/1-221213200P53R.png)