ASTM A213 ASME SA213 TP347HFG Seamless Steel Tubes

ASTM A213 ASME SA213 TP347HFG Seamless Steel Tubes

1 Introduction

TP347HFG is a chromium nickel niobium austenitic stainless steel with the same composition as TP347H, but with different processing technology.

Sumitomo Japan has improved two problems of TP347H (one is that the smoke and steam side of TP347H will produce oxide layer peeling off under the action of thermal cycle, and then block at the elbow, resulting in overheating and failure; the other is that the peeled oxide will be brought into the turbine, resulting in serious erosion of the turbine). The mechanism of dissolution and precipitation of fine niobium carbide (NBC) is adopted The new heat treatment process with higher solution treatment temperature makes the grain of TP347H greatly refined. The mechanical properties at room temperature and high temperature are basically the same as those of TP347H. Because the steel is niobium stable austenitic steel, and the grain is obviously refined, the endurance strength is about 20% higher than the ASME code value, the welding performance and fatigue performance are much better than the conventional TP347H steel pipe, and it has good intergranular corrosion resistance, good structure stability, more excellent oxidation resistance and peeling performance, in addition, it also has good bending performance; its comprehensive performance is obvious Better than TP347H. High temperature corrosion resistance of 18-8 stainless steel is the best. In recent years, the steel has been approved by ASME code case 2159 and listed in ASME SA213, named TP347HFG.

ASME SA213 TP347HFG Seamless Steel Tubes Quick Details

Manufacture:Seamless process

Common specifications:50.8mm*10.8mm, 45mm*7.5mm, 70mm*8mm,

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished to prevent rust.

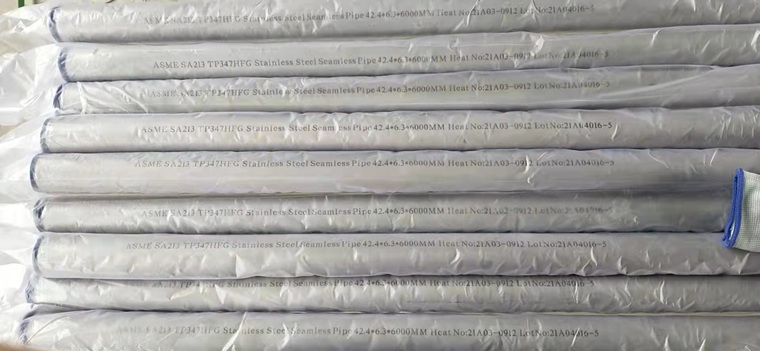

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

Application of ASTM A213 ASME SA213 TP347HFG Seamless Steel Tubes

Like TP347H, ASME SA213 TP347HFG steel tubes are mainly used to manufacture high temperature superheater, high temperature reheater, high temperature section of platen superheater and various high temperature and high pressure resistant pipe fittings of large-scale power generation boiler with supercritical pressure parameters. However, for pressure bearing parts, the maximum working temperature should be higher. Because its comprehensive performance is much better than TP347H, it should be widely used in the future Use.

TP347HFG steel was used in the superheater and reheater materials of the first 700MW, 22.7mpa, 566 / 566 / 566 ℃ ultra supercritical boiler of Chubu Electric Power Co. 's Kawagoe power stage in Japan in 1989.

Chemical composition (%)

| Standard | C | Mn | Si | P | S | Cr | Ni |

| ASME code case 2159 | 0.06-0.10 | ≤2.00 | ≤0.75 | ≤0.040 | ≤0.030 | 17-20.0 | 9.0-13.00 |

Metallographic structure

The supply status of ASME SA213 TP347HFG seamless steel tubes are solution treatment. Three processes are required: first, initial solution treatment (the solution treatment temperature is 50 ℃ higher than the final solution treatment temperature); second, cold processing; third, final solution treatment at a temperature not lower than 1180 ℃. After three processes, the microstructure should be single supersaturated austenite, and the grain size should be 7-10.

Mechanical property

Mechanical properties at room temperature

| Standard | Tensile properties (longitudinal) |

Hardness HRB(HB) |

||

|

Yield Strength

(MPa) |

Tensile strength (MPa) |

Elongation(%) | ||

| ASME code case 2159 | ≥205 | ≥550 | ≥35 | ≤90(192) |

Endurance strength σ (MPA)

| Standard | 600℃ | 621℃ | 640℃ | 650℃ | 677℃ | 700℃ | 732℃ |

| ASME code case 2159 | 131.1 | 129.5 | 109.3 | 98 | 75.1 | 58.4 | 41 |

Allowable stress σ (MPA)

| Temperature (℃) | 525 | 550 | 575 | 600 | 625 | 650 | 675 | 700 | 732 |

| ASME code case 2159 | 90.7 | 89.9 | 89.1 | 87.8 | 83.9 | 66.2 | 51.5 | 39.1 | 27.5 |

Oxidation resistance and corrosion resistance

The steam oxidation resistance test of ASME SA213 TP347HFG at 650 and 700 ℃ shows that its steam oxidation resistance is much better than that of conventional TP347H steel pipe, and the smaller the grain, the better the oxidation resistance; the oxidation corrosion depth under the same conditions is about half of the latter.

The high temperature corrosion resistance test results of TP347HFG steel in coal ash environment (temperature 650 ℃, atmosphere 1% SO2 + 5% O2 + 15% CO2 + baln2) with synthetic ash (1.5mol K2SO4 + 1.5mol Na2SO4 + 1.0mol Fe2O3)) show that its high temperature corrosion resistance is equal to or better than that of conventional TP347H steel pipe, and the smaller the grain, the better the high temperature corrosion resistance.

Heat treatment

The supply state of TP347HFG steel tubes are solution treatment. Three processes are required: first, initial solution treatment (the solution treatment temperature is 50 ℃ higher than the final solution treatment temperature); second, cold processing; third, final solution treatment at a temperature not lower than 1180 ℃.

Welding performance

Because of the grain refinement of TP347HFG steel, its weldability is better than that of TP347H. The hot cracking sensitivity test shows that compared with the conventional TP347H, it has less cracking and less possibility of cracking.

Welding of the same kind of steel

Manual, automatic and semi-automatic gas tungsten arc welding (GTAW) or shielded metal arc welding (SMAW) can be used; for GTAW, the corresponding welding material (filler metal) is taseto tg347 (manufactured by Nippon Oil & faths Co., Ltd.) or er347 (AWS); for SMAW, the corresponding welding material (filler metal) is taseto rny347 or e347 (AWS). When welding, the control layer temperature shall not exceed 150 ℃. The post weld heat treatment of 1170-1200 ℃ and 15-30 minutes can be adopted after welding. However, if appropriate protective measures can be taken for the Chloride Erosion in the heat affected zone of welding, the post weld heat treatment can not be carried out.

Dissimilar steel welding

A) Compared with T91, the filler material ernicr-3, no preheating / layer temperature (minimum 250 ℃) and post weld heat treatment (700-730 ℃);

B) With T22, the welding material ernicr-3, no preheating / layer temperature (minimum 250 ℃) and post weld heat treatment (700-730 ℃) or no post weld heat treatment.

Pipe bending

Cold bending

The cold deformation of TP347HFG steel has an effect on the endurance strength. Therefore, after bending deformation (or bending radius reaches 10dr, but large residual tensile stress occurs), all pipes shall be subject to solution treatment after bending, with the same process as post weld heat treatment; if appropriate protection measures cannot be taken for chloride erosion, all bends shall be treated.

Hot bending

Unless the hot working temperature is controlled at 1170-1200 ℃, the solution treatment must be carried out again to restore the normal permanent strength performance of TP347HFG steel.

Images of ASTM A213 ASME SA213 TP347HFG Seamless Steel Tubes

![field:title/]](/uploads/230313/1-230313123913C5.jpg)

![field:title/]](/uploads/221029/1-221029152602104.png)

![field:title/]](/uploads/221029/1-221029151P2200.png)

![field:title/]](/uploads/191012/1-19101213593J94.jpg)

![field:title/]](/uploads/220915/1-220915122A2E0.jpg)

![field:title/]](/uploads/220829/1-220R9214425M5.png)

![field:title/]](/uploads/200203/1-2002031G403Z3.jpg)