ASTM A213 ASME SA-213 TP347 Seamless Steel Tubes

ASTM A213 ASME SA-213 TP347 Seamless Steel Tubes

ASTM A213 ASME SA-213 TP347 stainless steel pipe is austenitic stainless acid-resistant steel, widely used in aviation, petrochemical, food, paper and other industries, such as aero-engine exhaust manifolds and branch pipes, turbo compressor hot gas pipes and Equipment and accessories that work under the condition of small load and temperature not exceeding 850℃.

Standard: ASTM A213, ASME SA213

Equivalent Standards: EN 10216-5, DIN 17458, GOST 9941-81, GOST 9940-81

ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A213 ASME SA-213 TP347 Stainless Steel Tubes Quick Details

Country/Region: China

Product Name:ASTM A213 ASME SA-213 TP347 Stainless Steel Tubes

FOB Price: US $4000-5000 / Ton | 1 Ton/Tons (Min. Order)

Specifications: 57mm*8mm; 60mm*9mm; 45mm*11mm, 51mm*12mm etc.

Payment:L/C or T/T

Package:Standard export package,suit for all kinds of transport, or as required

Materials and Manufacture

Manufacture and Condition—Tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified.

Heat Treatment:

TP347 Stainless Steel Tubes are Austenitic Stainless Steels—All austenitic tubes shall be furnished in the heat-treated condition, and shall be heat treated in accordance with the requirements of Table 1

Heat Treatment and Grain Size of SA213 TP347 Seamless Steel Tube (Table 1)

| Grade | Heat treatment | Solution treatment temperature,℃ | Cooling medium | ASTM grain size class number |

| TP347/S34700 | solution treatment. | 1900 [1040] | Water cooling or rapid cooling | -- |

Chemistry Composition of ASTM A213 ASME SA-213 TP347

| C, % | Si, % | Mn, % | P, % | S, % | Cr, % | Ni, % | Nb, % |

| 0.08 max | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 17.0-20.0 | 9.0-13.0 | 10*C-1.1 |

Mechanical Properties of ASTM A213 ASME SA-213 TP347

| Grade | Tensile Strength , MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| TP347/S34700 | 515 min | 205 min | 35 min | 192 max |

Physical constants of TP347 stainless steel tube

Melting point: 1398-1427℃

Density: 7.9g/cm3

Specific heat capacity: 500J (kg.K)

Modulus of elasticity: 196GPa at 20℃, 186GPa at 200℃, 177GPa at 400℃, 167GPa at 500℃, 167GPa at 600℃

Specific resistance: 0.75nN.m

Outside Diameter & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

Wall thickness & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

Inspection & Test:

Chemistry composition,

Tensile test,

Hardeness test,

Flattening test,

Flaring test,

NDT,(Hydrostatic or Nondestructive Electric Test)

Surface inspection and dimension check.

Surface Condition

ASTM A213 ASME SA-213 TP347 Stainless steel tubes shall be pickled free of scale.

When bright annealing is used, pickling is not necessary.

Any special finish requirement shall be subject to agreement between the supplier and the purchaser.

ASTM A213 ASME SA-213 TP347 Stainless Steel Tube Corrosion Resistance:

TP347 stainless steel pipe is characterized by good resistance to intergranular corrosion, and has good corrosion resistance in acid, alkali, salt and other solutions.

Intergranular corrosion: Tested by copper sulfate plus sulfuric acid plus copper chips method (T method), copper sulfate plus sulfuric acid method (L method) and 65% HNO3 method (X method).

Oxidation resistance: In the air at 750-800 ℃, this steel has stable oxidation resistance.

TP347Steel Can be welded with ER347 wire.

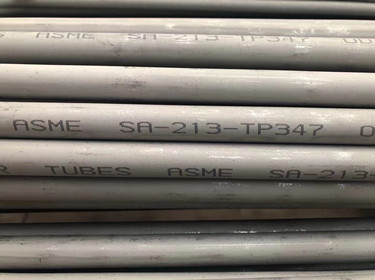

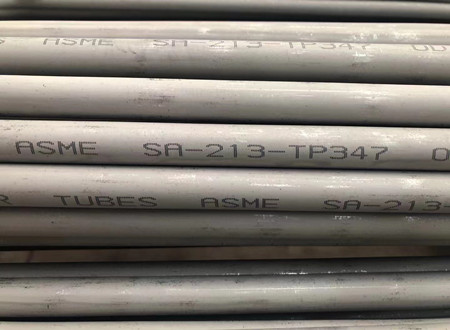

Photos of ASTM A213 TP347 Seamless Steel Tubes

![field:title/]](/uploads/230313/1-230313123913C5.jpg)

![field:title/]](/uploads/221029/1-221029152602104.png)

![field:title/]](/uploads/221029/1-221029151P2200.png)

![field:title/]](/uploads/200115/1-200115110515418.png)

![field:title/]](/uploads/191012/1-19101213593J94.jpg)

![field:title/]](/uploads/220829/1-220R9214425M5.png)

![field:title/]](/uploads/200203/1-2002031G403Z3.jpg)